Exploring the Double Pig System: A Modern Advancement in Pipeline Efficiency

In the fluid transfer industry, improving operational efficiency, minimizing product loss, and reducing downtime are top priorities. Whether transporting food-grade products, chemicals, paints, or pharmaceutical fluids, manufacturers need solutions that are both cost-effective and hygienic. One such innovative solution gaining attention is the double pig system. This advanced pigging configuration takes traditional single-pig systems a step further by using two pigs within the same pipeline, significantly enhancing cleaning and product recovery capabilities.

This article explores the functionality, advantages, applications, and design considerations of the double pig system, making it clear why many manufacturers are upgrading to this smart pipeline technology.

What Is a Double Pig System?

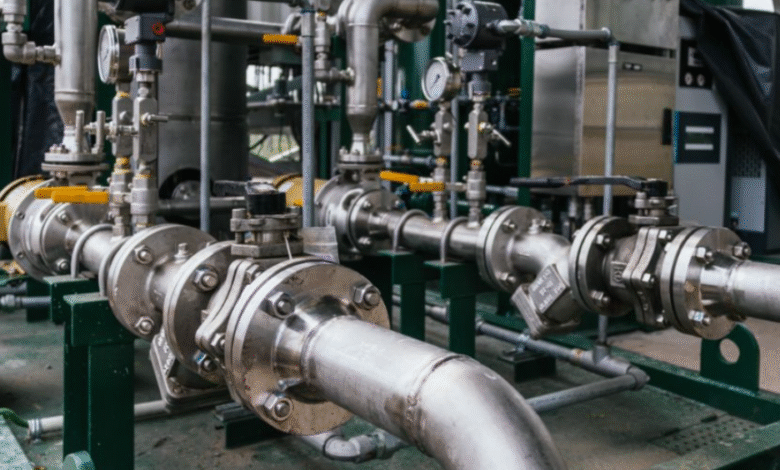

A double pig system is a type of pigging technology that uses two pigs instead of one in a single cleaning or product recovery cycle. These pigs are usually made of flexible, sanitary-grade materials such as silicone, polyurethane, or rubber. The pigs are separated by a volume of air, gas, or even water to create a sealed space, often referred to as the “slug,” which serves to push product efficiently and cleanly through the pipeline.

Unlike traditional systems that use a single pig to push residual product through the line, the double pig system provides more control over the separation of different products or phases within the line. It is especially beneficial for industries handling multiple products with high hygiene or contamination sensitivity.

How the Double Pig System Works

The typical process in a double pig system includes the following steps:

- Pig Launching: Two pigs are loaded into the pipeline—one at the front of the product and one behind it. A driving medium (usually compressed air, nitrogen, or water) is injected to push the front pig forward.

- Product Separation: The product to be transferred is contained between the two pigs, ensuring no mixing with the driving medium or residues from previous batches.

- Pig Receiving: Once the product has been delivered to the desired destination, both pigs are collected at a receiver station. The pipeline is now nearly empty of product and requires minimal cleaning.

This design not only improves product yield but also prevents cross-contamination—an essential feature for industries that deal with high-purity products.

See also: Fanvil Dubai: Elevating Business Communication Solutions

Components of a Double Pig System

A fully functional double pig system generally consists of:

- Pig Launchers and Receivers: These units load and collect pigs at the start and end of the pipeline.

- Piggable Valves: Full-bore valves that allow the smooth passage of pigs.

- Pigs: Typically foam, solid, or gel types, depending on the product and pipeline conditions.

- Pressure Control Equipment: Compressors, pumps, or pressurized tanks for moving the pigs and product.

- Sensors and Controls: Used to track pig position, monitor system pressure, and automate flow transitions.

Benefits of a Double Pig System

✅ Superior Product Recovery

One of the key advantages of the double pig system is the ability to recover nearly all of the product from the pipeline. Because the product is encapsulated between two pigs, it can be pushed out more cleanly, with minimal residual waste.

✅ Improved Hygiene and Safety

In industries such as food, beverage, and pharmaceuticals, product purity and cleanliness are critical. The double pig system prevents mixing of cleaning agents, products, and air with the transported material, reducing the risk of contamination.

✅ Faster Changeovers

For manufacturers who process multiple products on the same line, the double pig system allows for rapid and clean product changeovers. This significantly reduces downtime and increases batch flexibility.

✅ Reduced Water and Chemical Usage

Since the double pig system removes more product than traditional cleaning methods, the need for Clean-in-Place (CIP) processes is reduced. This leads to lower usage of water, detergents, and energy.

✅ Cost Efficiency

While initial investment may be higher than single pig systems, the long-term savings in product recovery, cleaning resources, and labor make the double pig system highly cost-effective.

Industries Benefiting from Double Pig Systems

🧴 Cosmetic and Personal Care

Products such as creams, gels, and shampoos are high in viscosity and value. The double pig system allows for maximum product recovery and keeps lines free of residue, which is especially important for maintaining texture and formulation integrity.

🥫 Food and Beverage

From sauces and syrups to dairy and fruit purees, many food products are sensitive to contamination. Double pigging ensures clean transitions between recipes and protects product flavor, color, and consistency.

💊 Pharmaceuticals

In pharmaceutical manufacturing, batch integrity is crucial. The double pig system supports sterile, hygienic transfer of liquid drugs and APIs (Active Pharmaceutical Ingredients), reducing the risk of cross-contamination.

🧪 Chemical Processing

When transporting adhesives, paints, solvents, or lubricants, minimizing waste and preventing dangerous mixing reactions are essential. Double pigging provides better control in these high-stakes scenarios.

Future Trends in Double Pigging Technology

As technology advances, double pig systems are evolving to be even more efficient and intelligent. Emerging trends include:

- Smart Pigs: Embedded with sensors to monitor temperature, pressure, or detect leaks during transfer.

- Remote Monitoring: IoT-enabled pigging systems allow real-time tracking from a central dashboard.

- Eco-Optimized Pigs: Made from biodegradable or recyclable materials for sustainability-conscious operations.

Conclusion

The double pig system is a game-changing innovation for companies aiming to optimize product transfer, ensure hygiene, and reduce operational waste. With industries becoming more competitive and environmentally conscious, solutions like double pigging offer an attractive blend of performance and sustainability.

If you’re still relying on single pig systems or traditional flushing methods, now might be the perfect time to explore the enhanced capabilities of double pigging. The results? Less product loss, faster changeovers, lower cleaning costs, and a cleaner, smarter pipeline.