Vacuum Forming Plastic: A Modern Approach to Custom Plastic Fabrication

Introduction

Whether for packaging, automotive parts, medical equipment, or signage, vacuum forming is transforming industries by offering lightweight, durable, and customized plastic solutions. The process is ideal for both prototyping and low-to-medium volume production, making it a preferred choice for startups and large manufacturers alike.

This article explores what vacuum forming plastic is, how it works, the materials involved, benefits, applications, and why it continues to gain popularity in a competitive manufacturing landscape.

What Is Vacuum Forming Plastic?

The final product can then be trimmed, finished, and used as a standalone part or in a larger assembly.

Unlike injection molding, which involves high tooling costs and is ideal for large volumes, vacuum forming is relatively simple, cost-effective, and perfect for short-run production or prototypes.

How the Vacuum Forming Process Works

Here’s a step-by-step overview of how plastic parts are made through vacuum forming:

1. Design Phase

Engineers or designers create a CAD file that defines the desired part. The design must consider material behavior, thickness distribution, and mold geometry.

2. Mold Creation

A mold is made using aluminum, wood, resin, or 3D-printed material. The mold may be positive (male) or negative (female), depending on the desired final product features.

3. Plastic Sheet Selection

A flat thermoplastic sheet—such as ABS, PETG, polystyrene, or polycarbonate—is chosen based on properties like flexibility, transparency, strength, and heat resistance.

4. Heating

The plastic sheet is clamped and heated in a forming machine until it reaches its forming temperature (typically between 300°F and 400°F depending on the material).

5. Forming

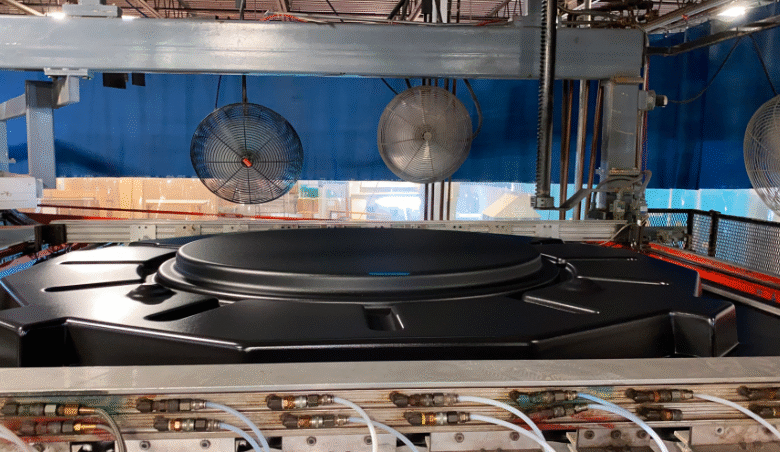

The heated plastic is draped over the mold. A vacuum is applied, pulling the plastic sheet tightly around the mold’s contours, ensuring all details are captured.

Types of Plastic Used in Vacuum Forming

- ABS (Acrylonitrile Butadiene Styrene): Tough and impact-resistant, used in automotive and consumer goods.

- HIPS (High Impact Polystyrene): Lightweight and affordable, ideal for disposable packaging.

- PETG (Polyethylene Terephthalate Glycol): Transparent and food-safe, often used for display cases and medical trays.

- PVC (Polyvinyl Chloride): Flame retardant and versatile, good for construction and industrial parts.

Each plastic type brings different mechanical, thermal, and visual properties to the table, which manufacturers consider based on project requirements.

Advantages of Vacuum Forming Plastic

1. Cost-Effective Tooling

Compared to injection molding, vacuum forming molds are inexpensive and quicker to produce, especially for prototype and limited runs.

2. Rapid Turnaround

The simplicity of the process allows for fast design-to-delivery cycles, which is ideal for businesses looking to test new products quickly.

3. Scalable Production

Vacuum forming is suited for both small-scale and medium-scale production, making it flexible for varying business needs.

See also: Transforming Your Business With Bookkeeping 8163077942

4. Design Flexibility

Complex shapes, textures, and patterns can be incorporated into designs without adding significant cost.

5. Lightweight Products

The end products are light yet durable, reducing transportation costs and easing handling in various applications.

6. Recyclable Waste

Excess plastic trim and unused sheets can often be recycled, reducing material waste and promoting sustainable practices.

Applications of Vacuum Forming Plastic

Automotive Industry

Dashboard panels, bumpers, wheel covers, and Vacuum forming plastic trunk liners are commonly produced through vacuum forming due to the need for custom, lightweight parts.

Packaging

Retail packaging, food trays, blister packs, and clamshells are all often vacuum-formed, providing both product protection and visual appeal.

Medical Field

Sterile trays, diagnostic housing units, and packaging for surgical instruments rely on vacuum forming for clean, precise forms.

Construction and Interior Design

Decorative panels, skylight covers, and wall trims benefit from vacuum forming’s ability to deliver customized and aesthetic solutions.

Signage and Advertising

Vacuum-formed signs offer three-dimensional visual impact, making them perfect for commercial displays and branding.

Challenges in Vacuum Forming

- Limited Detail in Deep Draws: Very deep or narrow molds may cause uneven material thickness or stretching.

- Single-Sided Molding: Only one side of the part (the mold side) has precise detail; the other side conforms to the sheet’s original surface.

- Lower Structural Strength: Vacuum-formed parts may not be as strong as injection-molded components and may require additional support.

However, these challenges can often be mitigated through good design practices, proper material choice, and collaboration with experienced manufacturers.

Innovations in Vacuum Forming Plastic

As the demand for efficient plastic solutions grows, vacuum forming continues to evolve:

- CNC Trimming: Automated trimming ensures high precision and repeatability.

- Hybrid Molds: Manufacturers are now using 3D printing and traditional materials to create hybrid molds faster and cheaper.

Conclusion

Vacuum forming plastic stands as a modern, efficient, and highly customizable manufacturing process that serves diverse industries. With its low-cost tooling, fast turnaround, and design adaptability, it’s an excellent choice for prototyping and short-run production. By selecting the right materials and understanding the process, businesses can bring their plastic component ideas to life with speed and precision.

As technology and materials continue to advance, the scope of vacuum forming will only grow wider. For companies looking to enter this space or upgrade their current manufacturing approach, partnering with experienced vacuum forming specialists can unlock new levels of innovation and efficiency.