Exploring Gas Chromatography Equipment: Essential Tools for Modern Laboratories

In the world of analytical chemistry, precision, speed, and sensitivity are non-negotiable. Among the most powerful techniques used for separating and analyzing compounds is gas chromatography, often abbreviated as GC. At the heart of this technique lies the indispensable tool: gas chromatography equipment. Whether it’s used in environmental testing, food safety, pharmaceuticals, petrochemicals, or forensic science, this equipment has proven to be a cornerstone of reliable chemical analysis.

This article delves into the significance, components, applications, and considerations when selecting gas chromatography equipment, providing laboratories and research facilities with an all-in-one resource for making informed purchasing decisions.

What Is Gas Chromatography Equipment?

gas chromatography equipment refers to a set of instruments and components designed to separate and analyze compounds that can be vaporized without decomposition. Unlike liquid chromatography, which uses liquids as the mobile phase, gas chromatography utilizes an inert gas (commonly helium or nitrogen) to carry a sample through a column packed with a stationary phase.

This type of equipment is primarily used to:

- Detect trace elements in mixtures

- Quantify components

- Purify chemical compounds

- Monitor chemical processes

Gas chromatography equipment delivers extremely high resolution and rapid results, making it ideal for both qualitative and quantitative analysis.

See also: Sources Amazon Alexa June Businessinsider

Core Components of Gas Chromatography Equipment

To understand the technology better, let’s break down its main components:

1. Carrier Gas Supply

The carrier gas is the mobile phase that transports the sample through the column. It must be pure and stable. Common choices include helium, hydrogen, and nitrogen.

2. Injector

The injector introduces the sample into the system. Most injectors are heated to instantly vaporize the sample, ensuring it enters the column in a gaseous form.

3. Column

The analytical heart of the equipment. Columns are typically made of fused silica and contain a stationary phase coating. This is where the actual separation of compounds occurs.

4. Oven

A thermostatically controlled oven houses the column. It plays a crucial role in maintaining consistent temperatures to influence compound separation.

5. Detector

Detectors identify and quantify compounds as they exit the column. Common types include:

- Flame Ionization Detector (FID)

- Thermal Conductivity Detector (TCD)

- Electron Capture Detector (ECD)

- Mass Spectrometer (GC-MS coupling)

6. Data System

Modern gas chromatography equipment is equipped with software for data acquisition, peak identification, quantification, and reporting.

Applications Across Industries

The versatility of gas chromatography equipment makes it valuable across diverse sectors:

✔ Environmental Testing

Used to detect pollutants such as pesticides, hydrocarbons, and industrial solvents in air, water, and soil samples.

✔ Food and Beverage

Helps identify contaminants, additives, and flavor profiles in products, ensuring food safety and regulatory compliance.

✔ Pharmaceuticals

Ensures drug purity, validates formulations, and checks for residual solvents in pharmaceutical products.

✔ Petrochemicals

Monitors fuel composition, refinery processes, and the quality of crude oil derivatives.

✔ Forensic Science

Analyzes blood alcohol content, accelerants in arson cases, and trace evidence from crime scenes.

Types of Gas Chromatography Equipment

When selecting gas chromatography equipment, it’s essential to understand the variations available based on application needs:

1. Benchtop GC Systems

Ideal for small laboratories or educational settings. These systems are compact, affordable, and often used for routine analysis.

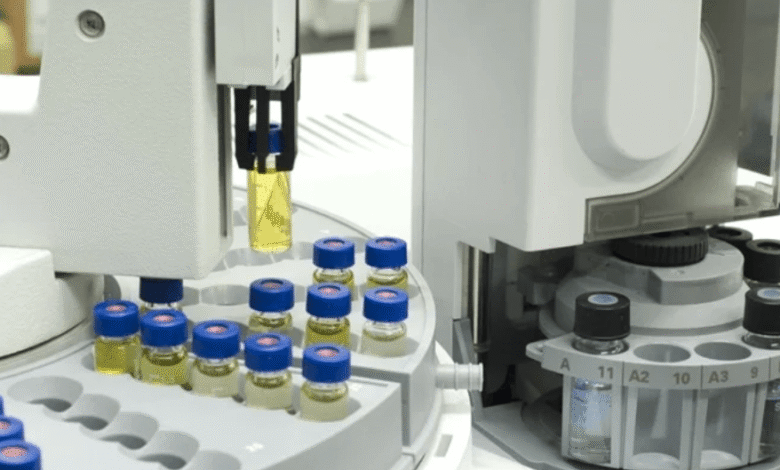

2. Automated GC Systems

Feature autosamplers and robotic arms to increase throughput and reduce human error. Ideal for high-volume testing environments.

3. GC-MS (Gas Chromatography–Mass Spectrometry)

Couples gas chromatography with mass spectrometry to provide highly sensitive, specific, and powerful compound identification.

4. Portable GC Units

Lightweight models designed for field analysis—particularly useful for environmental and security applications.

Considerations When Choosing Gas Chromatography Equipment

Buying gas chromatography equipment is a significant investment. Here are key factors to evaluate:

🧪 Analytical Needs

What types of samples will you analyze? What level of sensitivity and resolution is required? Answering these helps define detector type, column specs, and software capabilities.

🧰 Ease of Use

Choose equipment with user-friendly interfaces and automation features. This minimizes training time and maximizes efficiency.

💡 Detector Options

Different detectors serve different analytical purposes. For example:

- FID is excellent for hydrocarbons.

- ECD is sensitive to halogenated compounds.

- MS provides detailed compound structure.

🔧 Maintenance and Support

Reliable gas chromatography equipment should come with a service plan, technical support, and easy-to-replace components.

💰 Cost vs. Performance

Balancing budget and capability is critical. Higher-end systems offer more features, but may not be necessary for every lab.

Top Features to Look For

When evaluating different systems, prioritize these modern features:

- Touchscreen operation and intuitive GUI

- Built-in auto-calibration

- Real-time diagnostics

- Remote monitoring and troubleshooting

- Multi-detector support

- Compliance with GLP/GMP standards

These features not only improve operational efficiency but also future-proof your investment.

Role of a Reputable Supplier

Choosing the right gas chromatography equipment also depends heavily on your supplier. A reliable supplier should offer:

- Technical consultation before purchase

- Product demos or trial periods

- Installation and on-site training

- Warranty coverage and maintenance plans

- After-sales service and spare part availability

Whether you’re upgrading an existing setup or building a new laboratory, the supplier becomes your long-term partner in success.

Training and Safety Considerations

Since gas chromatography equipment deals with high temperatures, flammable gases, and sometimes toxic substances, proper training is vital. Labs should ensure:

- All users are trained in safety and operation

- Regular maintenance schedules are followed

- Emergency procedures are established

- Gas leak detectors and ventilation are in place

Manufacturers often provide training as part of the onboarding process. Choose suppliers who include or recommend certified operator programs.

Future Trends in Gas Chromatography

As technology continues to evolve, so does gas chromatography equipment. Some exciting developments include:

- Miniaturized GC systems for field applications

- AI-powered analysis software to improve compound detection accuracy

- Hydrogen carrier gas generators to reduce dependence on helium

- Automated sample prep integration

- Green chemistry initiatives for lower environmental impact

Staying updated on these trends ensures you remain competitive and efficient in your laboratory operations.

Conclusion

Gas chromatography is a vital analytical tool in scientific research and industrial applications. Whether you’re analyzing food, fuel, pharmaceuticals, or forensic evidence, choosing the right gas chromatography equipment ensures your results are accurate, reliable, and reproducible.

Investing in quality equipment—and a reliable supplier—is more than a procurement decision; it’s a long-term commitment to precision and progress. As analytical demands continue to rise, having the right tools in your lab could be the defining factor in your success.