Why sheet metal fabrication service Is the Backbone of Modern Manufacturing

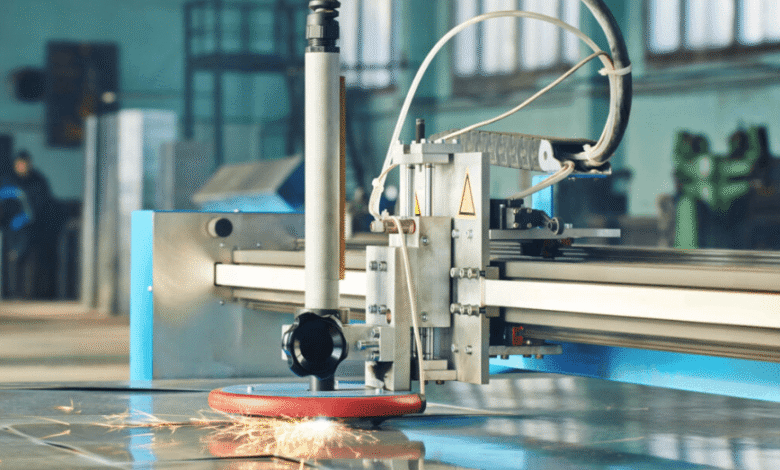

In the rapidly advancing world of manufacturing, innovation and flexibility are more important than ever. One of the unsung heroes in this realm is the sheet metal fabrication service, which plays a pivotal role across numerous industries, from aerospace and automotive to electronics and construction. This service is the foundation upon which countless components, devices, and structures are built.

As businesses strive for cost-efficiency, high precision, and quick turnaround times, opting for a reliable sheet metal fabrication service has become a strategic decision. Let’s explore why sheet metal fabrication is essential, what processes are involved, and how to choose the right service provider for your needs.

What Is a sheet metal fabrication service?

A sheet metal fabrication service refers to a set of industrial processes used to create metal structures or parts from flat sheets of metal. These sheets are cut, bent, and assembled into specific shapes or assemblies using specialized tools and techniques. The metals used often include stainless steel, aluminum, copper, and galvanized steel.

The service is tailored to both prototype and full-scale production runs, offering solutions for diverse needs like enclosures, chassis, brackets, and custom assemblies.

Key Processes in sheet metal fabrication service

To understand the versatility and value of a sheet metal fabrication service it’s important to recognize the core processes involved:

1. Cutting

This is the initial step where metal sheets are cut into required shapes or dimensions. Cutting methods include:

- Laser Cutting – precise and clean for complex geometries.

- Plasma Cutting – effective for thicker materials.

- Waterjet Cutting – good for heat-sensitive materials.

- Shearing – used for straight-line cuts on thin sheets.

2. Bending

After cutting, sheets often need to be bent into desired angles. CNC press brakes are used for accurate, repeatable bends without compromising structural integrity.

3. Punching

Holes or patterns can be added using turret punches or CNC punching machines. This is useful in ventilation panels, mounting holes, or decorative designs.

4. Welding

Assembled parts are welded together using methods like MIG, TIG, or spot welding. Welding ensures durability and strength in the final product.

5. Assembly and Finishing

Fasteners, rivets, or adhesives may be used to complete the assembly. The final steps might include powder coating, painting, polishing, or anodizing to improve appearance and resistance to wear or corrosion.

See also: Sources Amazon Alexa June Businessinsider

Advantages of Choosing a Professional sheet metal fabrication service

✅ Precision and Customization

Modern sheet metal fabrication facilities utilize CNC (Computer Numerical Control) machinery that ensures micron-level precision. Whether you need a one-off prototype or 10,000 identical pieces, the process remains consistent and repeatable.

✅ Cost-Efficiency

High production speed and automation reduce manual labor, making the process more cost-effective. Moreover, materials like aluminum or steel sheets are generally less expensive than molded or cast alternatives.

✅ Scalability

Whether you’re a startup looking for a low-volume run or a corporation needing mass production, sheet metal fabrication service can scale to your requirements seamlessly.

✅ Durability and Strength

Metal parts produced through fabrication are strong, corrosion-resistant, and capable of withstanding extreme conditions—ideal for structural or load-bearing applications.

✅ Speed of Turnaround

Thanks to automation and well-structured workflows, turnaround times are shorter than ever. Quick prototyping allows businesses to bring products to market faster.

Applications of sheet metal fabrication service

From household items to industrial components, the reach of sheet metal fabrication service is extensive:

- Aerospace: Creating lightweight, high-strength brackets, panels, and housings.

- Automotive: Manufacturing car body parts, engine components, and interior mounts.

- Electronics: Custom enclosures for PCs, telecom devices, or audio systems.

- Medical Equipment: Surgical table frames, brackets, and diagnostic machine covers.

- Architecture: Custom signage, cladding, ventilation systems, and staircases.

How to Choose the Right sheet metal fabrication service

When selecting a provider, consider the following:

1. Experience and Reputation

Check how long the company has been in business and what industries it serves. A well-established provider is more likely to deliver quality results on time.

2. Technical Capabilities

Do they offer laser cutting, CNC bending, robotic welding, and finishing in-house? The broader their capabilities, the more streamlined and cost-effective your project will be.

3. Certifications

ISO 9001, ISO 13485 (medical), or AS9100 (aerospace) certifications demonstrate adherence to quality standards and process control.

4. Prototyping Support

Look for services that offer prototyping and design consultation. This is critical if you’re developing a new product.

5. Turnaround and Lead Times

A good sheet metal fabrication service provider should meet tight deadlines without sacrificing quality. Clear communication and transparency about delivery timelines are essential.

sheet metal fabrication service Trends in 2025 and Beyond

Technology and sustainability are shaping the future of sheet metal work. Key trends include:

• Smart Factories and IoT Integration

Data-driven fabrication enables real-time monitoring of machines and predictive maintenance, reducing downtime and improving output quality.

• 3D Metal Printing Integration

While still emerging, combining 3D printing with sheet metal parts allows for faster, hybrid manufacturing strategies, especially for low-volume, complex parts.

• Sustainability Practices

Using recyclable metals, minimizing material waste, and adopting cleaner finishing techniques are making the industry more eco-friendly.

• Advanced Materials

In addition to common alloys, more shops are beginning to fabricate parts using high-performance materials like titanium, Inconel, and magnesium for specialized applications.

Challenges in sheet metal fabrication service

Despite its many benefits, there are a few challenges to consider:

- Material Waste: Inefficient nesting or overcutting can lead to excess scrap.

- Complexity of Design: Not all designs are feasible with standard tooling; understanding manufacturability is crucial.

- Skilled Labor Shortage: Though automation helps, experienced operators are still essential for quality control and setup.

Conclusion

A reliable sheet metal fabrication service is a crucial asset in any manufacturing strategy. It bridges the gap between concept and physical product with unmatched precision, efficiency, and scalability. Whether you’re building the next-gen medical device or a high-performance automotive component, the right fabrication partner ensures you get the results you need—on time, on budget, and up to standard.

As industries evolve and demand more customization, faster delivery, and tighter tolerances, sheet metal fabrication will only become more indispensable. For businesses aiming to maintain a competitive edge in today’s landscape, investing in quality sheet metal fabrication service is no longer optional—it’s a necessity.