How to Choose the Right Compression Springs Manufacturer for Your Industry Needs

Compression springs are one of the most essential mechanical components used in a wide range of industries. From automotive and aerospace to medical devices and consumer electronics, compression springs provide critical functions such as absorbing shock, storing energy, and maintaining force between contacting surfaces. For engineers and procurement specialists, finding the right compression springs manufacturer is vital to ensure product reliability, performance, and cost efficiency.

This article will guide you through the importance of compression springs, key factors to consider when selecting a manufacturer, manufacturing processes, and how a quality compression springs manufacturer can help elevate your projects.

Understanding Compression Springs and Their Applications

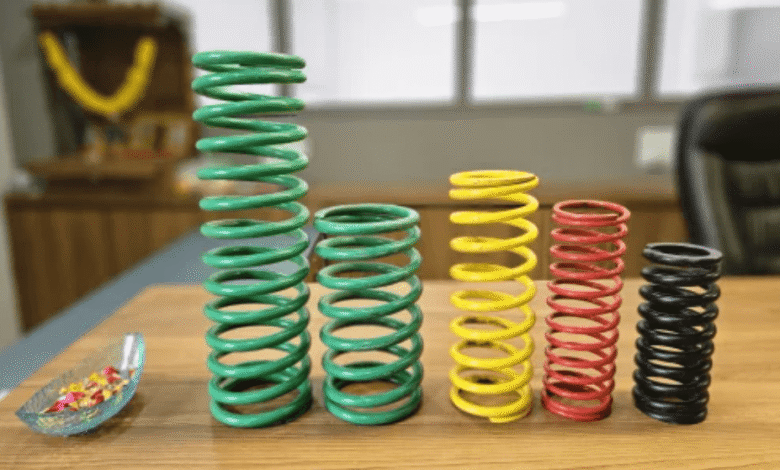

Compression springs are designed to resist compressive forces and return to their original length once the force is removed. They typically consist of helical coils made from metal wire and come in various sizes, materials, and configurations to suit specific load and space requirements.

Common Applications of Compression Springs

- Automotive Industry: Used in suspensions, clutches, and valve assemblies to absorb shocks and maintain contact pressure.

- Aerospace: Lightweight, high-strength springs help with vibration isolation and force control.

- Medical Devices: Precision springs in surgical instruments and implants provide controlled mechanical action.

- Industrial Machinery: Springs in presses, actuators, and safety devices ensure smooth operation.

- Consumer Electronics: Tiny compression springs in buttons and connectors enable reliable tactile feedback.

See also: Tech Support Number: 9133598435

The Role of a Compression Springs Manufacturer

A compression springs manufacturer specializes in designing and producing compression springs that meet precise specifications. Their expertise spans selecting appropriate materials, coil diameters, wire gauges, and heat treatments to optimize spring performance and durability.

Beyond producing standard springs, many manufacturers offer custom compression springs tailored to unique applications, including varying load capacities, dimensions, and environmental resistance.

Key Factors to Consider When Choosing a Compression Springs Manufacturer

1. Manufacturing Expertise and Experience

Look for manufacturers with a proven track record of producing compression springs for your industry. Experienced manufacturers understand the nuances of spring design, material selection, and quality control critical for high-performance products.

2. Quality Certifications and Standards Compliance

Ensure the manufacturer complies with relevant industry standards such as ISO 9001 or aerospace certifications. Certifications indicate adherence to strict quality management and manufacturing protocols.

3. Material Options

The choice of material greatly affects spring behavior and lifespan. A versatile manufacturer offers a wide range of materials including stainless steel, music wire, phosphor bronze, and specialty alloys to meet specific needs like corrosion resistance or high-temperature performance.

4. Customization Capabilities

Whether you need a standard spring or a highly customized design, the manufacturer should accommodate custom dimensions, load ratings, coatings, and packaging requirements.

5. Advanced Manufacturing Technology

Modern manufacturing equipment such as CNC coiling machines, automated testing rigs, and heat treatment ovens improve precision, consistency, and production efficiency.

6. Supply Chain Reliability

Reliable manufacturers maintain sufficient inventory and efficient logistics to meet your delivery schedules, minimizing downtime.

7. Technical Support and Collaboration

A manufacturer with knowledgeable engineers can provide valuable input on spring design optimization and troubleshooting, enhancing overall product performance.

The Manufacturing Process of Compression Springs

Design and Specification

The process begins with detailed specifications including load requirements, dimensions, material, and environmental factors. Computer-aided design (CAD) software often assists in creating precise spring models.

Wire Selection

Selecting the right wire material and diameter is crucial for achieving the desired mechanical properties.

Coiling

High-precision coiling machines form the wire into helical shapes according to design specifications. Modern machines allow for varying coil pitches, diameters, and complex geometries.

Heat Treatment

Springs undergo heat treatment to relieve internal stresses and improve strength and flexibility.

Surface Finishing

Coatings such as zinc plating, powder coating, or phosphate finishes protect springs against corrosion and wear.

Quality Inspection

Final springs are tested for load, dimensional accuracy, and fatigue resistance using specialized equipment.

Benefits of Partnering with a Quality Compression Springs Manufacturer

Consistent High Quality

Reliable manufacturers deliver springs with uniform properties that meet exact specifications, ensuring consistent performance.

Cost-Effective Solutions

Expert manufacturers optimize material use and production processes, reducing waste and lowering costs without sacrificing quality.

Faster Time to Market

With efficient production and reliable supply chains, good manufacturers help accelerate project timelines.

Access to Innovation

Manufacturers invested in research and development provide access to advanced materials and design technologies.

Risk Reduction

Certified quality control minimizes the risk of spring failure and costly product recalls.

Industry Trends Affecting Compression Springs Manufacturing

Use of Advanced Materials

High-performance alloys and composite materials are increasingly used to improve strength-to-weight ratios and environmental resistance.

Industry 4.0 Integration

Smart manufacturing technologies such as IoT sensors and data analytics optimize production and quality control.

Sustainable Manufacturing

Manufacturers are adopting eco-friendly processes, reducing energy consumption and material waste.

Customization and Rapid Prototyping

Additive manufacturing enables faster prototyping of complex spring designs, speeding innovation cycles.

How to Maximize Your Relationship with a Compression Springs Manufacturer

- Clear Communication: Provide detailed design requirements and application information upfront.

- Collaborative Development: Engage engineers early for design feedback and optimization.

- Regular Quality Reviews: Establish inspection protocols and performance benchmarks.

- Flexible Ordering: Adjust order quantities based on project needs while maintaining lead times.

- Long-Term Partnership: Building trust enables better pricing, priority service, and co-development opportunities.

Conclusion

Choosing the right compression springs manufacturer is a critical decision that impacts the performance, reliability, and cost of your products. By partnering with an experienced and technologically advanced manufacturer, you gain access to high-quality, customized springs that meet your exact needs.

Invest time in evaluating manufacturers based on expertise, quality certifications, material capabilities, and customer service to ensure your projects achieve maximum success. Compression springs might be small, but their impact on product performance is immense—make sure you select a manufacturer who understands that.