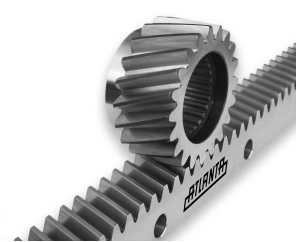

Precision gear rack: Enabling Precision Movement Across Industries

At the core of this system’s reliability and performance is the precision gear rack, an essential partner for industries ranging from automotive and robotics to heavy equipment and aerospace.

This comprehensive article explores the significance of rack and pinion systems, the roles of manufacturers in this sector, key features of high-quality products, innovations in design and production, and the criteria for choosing the best manufacturing partner.

Understanding the precision gear rack

Before diving into the manufacturer’s role, it’s essential to understand the basic structure and functionality of a rack and pinion system.

When the pinion rotates, its teeth push against the rack’s teeth, causing it to move in a straight line. This design is widely preferred for its simplicity, reliability, and effectiveness in numerous mechanical and automation applications.

Choosing the right precision gear rack can make or break the performance of your machine or system. These manufacturers are responsible not just for producing components, but for ensuring:

- Precision in geometry and tolerances

- Durability under high-load or repetitive-use conditions

- Consistency across production batches

- Custom engineering for specialized needs

From large OEMs (original equipment manufacturers) to small machine builders, all rely on competent rack and pinion suppliers to deliver flawless mechanical performance.

Applications of Rack and Pinion Systems in Modern Industries

1. Automotive Engineering

2. Industrial Automation

Rack and pinion assemblies are commonly found in robotic arms, pick-and-place systems, CNC machines, and other automation equipment where high-speed and high-precision linear motion is required.

3. Construction and Heavy Machinery

Cranes, lifts, and other heavy-duty systems use rack and pinion drives to provide strong, reliable, and controlled movement over vertical and horizontal axes.

4. Rail and Transit Systems

Some rail-based systems utilize rack and pinion drives to climb steep gradients or move through complex track layouts safely and efficiently.

Read also: Amazon Alexa June Aipowered Businessinsider

Core Responsibilities of a Rack and Pinion Manufacturer

To meet industry demands, manufacturers must handle a wide range of tasks and offer several capabilities:

1. Design and Engineering Support

A quality precision gear rack will work closely with clients to develop designs tailored to specific loads, speeds, environments, and applications.

2. Material Selection

Different applications require different materials:

- High-carbon steel for durability

- Stainless steel for corrosion resistance

- Nylon or composite materials for quiet operation in light-duty tasks

3. Gear Machining and Shaping

Manufacturers use advanced gear-cutting tools to machine rack and pinion teeth. Common methods include:

- Gear hobbing

- Milling

- Shaping

- Grinding

4. Heat Treatment and Surface Coating

For improved hardness and wear resistance, the components often undergo processes such as carburizing, nitriding, and induction hardening, followed by coatings like black oxide or phosphate.

Signs of a Trusted Rack and Pinion Manufacturer

If you’re sourcing a manufacturer, watch for these indicators of reliability and professionalism:

- ISO Certifications (e.g., ISO 9001, ISO/TS 16949)

- In-house Design & Engineering Teams

- Advanced CNC Machining and Heat Treatment Facilities

- References from Reputed Clients

- Clear Documentation and Traceability

- Quick Response and Quotation Turnaround Times

Manufacturing rack and pinion systems isn’t without challenges. Issues like misalignment, backlash, gear wear, and inaccurate tooth geometry can arise. Expert manufacturers use techniques like:

- Precision grinding for accurate profiles

- Anti-backlash systems

- Modular design for flexibility

- Lubrication optimization

- Laser measurement for tooth quality inspection

Case Study: How a Rack and Pinion Manufacturer Transformed a Robotics Startup

A robotics startup needed ultra-precise, backlash-free linear drives for their warehouse automation system.

- Problem: Standard components were either too bulky or not precise enough.

- Solution: Custom rack and pinion sets with special tooth profiles and integrated backlash compensation.

- Result: Improved motion accuracy by 40%, reduced downtime, and gained competitive edge in product performance.

Global Leaders in precision gear rack

Although many manufacturers exist globally, only a few stand out for quality, innovation, and customer service. These include companies based in:

- Germany (noted for precision engineering)

- Japan (known for robotics integration)

- USA (strong in OEM customization)

- Italy and Switzerland (gearing excellence)

When sourcing internationally, always evaluate reviews, technical support availability, and shipping reliability.

Tips for Working Successfully with Rack and Pinion Manufacturers

- Share detailed application requirements early

- Request prototype samples if possible

- Ask about lead times and delivery guarantees

- Evaluate their customization flexibility

- Clarify warranty and service terms

Conclusion

A precision gear rack is more than just a supplier — they are a critical enabler of precise, efficient, and durable mechanical motion across various sectors. Whether you’re building a robotic assembly line, designing an elevator, or creating a vehicle steering system, the quality and precision of your rack and pinion setup will define your system’s overall performance.

Choosing a reliable, experienced, and innovative manufacturer is essential to stay competitive in today’s engineering-driven world. As technology evolves, manufacturers that embrace customization, smart systems, and sustainable production will lead the future of rack and pinion technology.