Role of transformer oil purifier in power maintenance

Introduction

Transformer oil plays a critical role in the performance and reliability of power transformers by providing insulation and cooling. However, transformer oil gradually deteriorates due to contamination by moisture, gases, and particles. These contaminants reduce the oil’s insulating properties and can lead to equipment failure. A transformer oil purifier is essential equipment used to restore the quality of transformer oil by removing impurities. This article discusses the importance, working principles, and benefits of a transformer oil purifier in maintaining electrical transformers.

What is a transformer oil purifier?

A transformer oil purifier is a specialized device designed to clean transformer oil by eliminating moisture, dissolved gases, solid particles, and sludge. It employs techniques such as vacuum dehydration, filtration, and degassing to restore the oil’s dielectric strength and cooling efficiency. The purifier enables the reuse of transformer oil purifier reduces operational costs, and increases the reliability of transformers.

Why is transformer oil purification necessary?

Contaminated transformer oil poses several risks:

- Moisture: Water lowers the oil’s dielectric strength and causes corrosion.

- Dissolved gases: Indicate internal faults such as arcing or overheating.

- Solid particles and sludge: Lead to abrasion and block cooling pathways.

Purification ensures the removal of these impurities, improving oil quality and preventing transformer damage.

Components of a transformer oil purifier

The main components of a transformer oil purifier include:

- Heating unit: Warms oil to reduce viscosity and aid impurity removal.

- Vacuum chamber: Removes moisture and gases under low pressure.

- Filtration system: Multi-stage filters trap solids and sludge.

- Pump assembly: Circulates oil through the purifier.

- Control panel: Monitors temperature, vacuum, and operational parameters for efficient performance.

How does a transformer oil purifier work?

The purifier operates through these steps:

- The oil is heated to around 70-80°C to decrease viscosity.

- Heated oil enters the vacuum chamber where moisture and dissolved gases evaporate due to low pressure.

- The oil passes through filters that remove solid contaminants.

- Degassing removes residual gases, restoring oil purity.

This cycle continues until the oil meets the required quality standards.

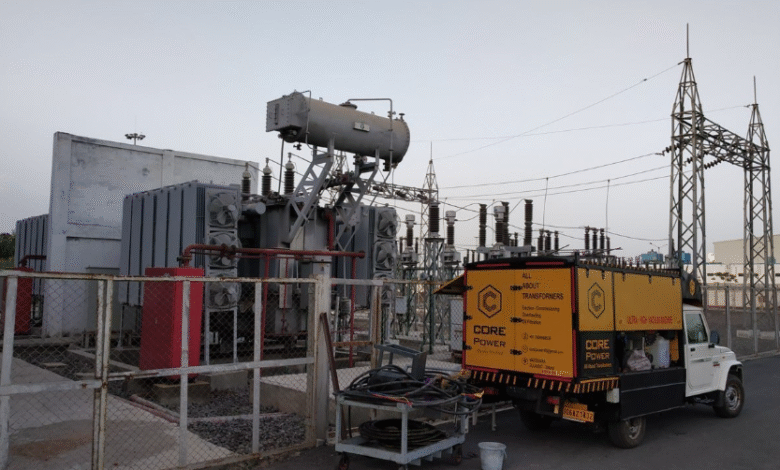

Applications of transformer oil purifiers

Transformer oil purifiers are widely used in:

- Power generation plants to maintain transformer health.

- Electrical substations for routine maintenance.

- Industrial facilities with large transformers.

- Renewable energy farms using wind and solar power.

- Transformer repair and oil recycling services.

Their use is critical to sustaining transformer reliability and extending oil life.

See also: Sources Amazon Alexa June Businessinsider

Benefits of using a transformer oil purifier

Cost-effectiveness

Purifying transformer oil reduces the frequency of oil replacement and costly transformer repairs.

Enhanced transformer performance

Clean oil maintains proper insulation and cooling, preventing equipment failures.

Environmental impact

Recycling transformer oil reduces hazardous waste and promotes sustainability.

Improved safety

Removing moisture and gases lowers the risk of electrical faults and fire hazards.

Maintenance of transformer oil purifiers

For optimal operation:

- Replace filters regularly to avoid clogging.

- Monitor vacuum, temperature, and pump performance.

- Inspect for leaks or damage in hoses and seals.

- Clean heating elements and vacuum chambers periodically.

- Schedule professional servicing for calibration and troubleshooting.

Proper maintenance extends purifier lifespan and ensures effective oil cleaning.

Technological advancements

Modern transformer oil purifiers feature:

- Automated control systems with real-time monitoring.

- Energy-efficient designs to lower power consumption.

- Portable units for on-site oil purification.

- Improved filter media for superior contaminant removal.

- IoT integration for predictive maintenance.

These advancements improve purification accuracy and ease of use.

Choosing the right transformer oil purifier

Factors to consider include:

- Volume and type of oil to be purified.

- Level of contamination and filtration requirements.

- Desired automation and user interface.

- Space constraints and portability needs.

- Budget and after-sales support.

Selecting the appropriate purifier ensures efficient and reliable oil treatment.

Conclusion

A transformer oil purifier is indispensable for maintaining transformer performance and prolonging oil life. By removing moisture, gases, and contaminants, it enhances transformer reliability, reduces operational costs, and supports environmental goals. Regular use of a transformer oil purifier combined with proper maintenance is key to achieving safe and uninterrupted power system operations.