Tension Control Bolts And Traditional Fasteners In Structural Engineering Applications

In structural engineering, the choice of fasteners is crucial for ensuring the integrity and longevity of constructions. The advancement in fastening technologies, particularly tension control bolts, represents a significant evolution in building methodologies and maintenance practices.

These advanced fasteners are not just an evolution from traditional methods but represent a leap forward in construction technology, offering enhanced efficiency, safety, and reliability.

Historical Context And Evolution

The history of fasteners in structural engineering reflects a story of continuous innovation. From basic nuts and bolts to advanced tension control bolts, this transition signifies a major shift in construction methodologies.

Traditional fasteners, while foundational in the past, often fell short in efficiency and safety. Their introduction marked a new era, enhancing construction processes with greater efficiency and safety.

For more information on these fastening solution bacoent.com/category/155/Tension-Control.html

Understanding Advanced Fastening Solutions

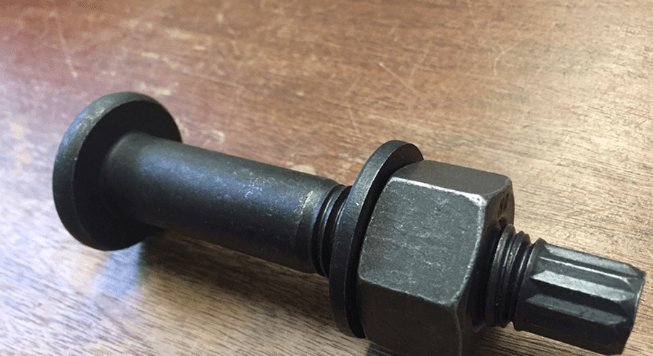

These bolts come in various types, each designed for specific structural requirements and offering unique strengths and durability.

Detailed Overview Of Bolt Types

A325: These are commonly used in A325 tension control bolts have a high strength level, making them suitable for heavy-load applications.

A490: Similar to A325, but with even higher strength. They are often used in critical structural applications where higher load capacities are required.

Galvanized: These are A325 or A490 galvanized tension control bolts with a galvanized coating, providing enhanced corrosion resistance. They are ideal for outdoor or corrosive environments.

F1852: A type of twist-off tension control bolt that is equivalent to A325 bolts. They are known for their ease of installation and are commonly used in building and bridge construction.

ASTM A307: These bolts have a lower strength compared to A325 and A490 but are suitable for standard load applications. They are often used in non-critical structural applications or where shear loading is predominant.

BACO Enterprises Inc. offers a comprehensive range of these bolts, catering to various structural needs with a focus on quality and innovation.

Popular Finishes

The finishes applied to bolts play a vital role in their performance and longevity. Common finishes include plain (uncoated), zinc plating, and hot-dip galvanizing. The choice of finish depends on the application environment and structural requirements.

Traditional Fasteners In Structural Engineering

Traditional fasteners like nuts, bolts, and screws have been fundamental in structural connections for centuries. However, compared to tension control bolts, they have limitations in tension consistency and structural integrity.

Despite these limitations, they continue to be used for their simplicity and cost-effectiveness, though these bolts are increasingly recognized for their advanced capabilities in critical applications.

Technical Aspects

The design and functionality set them apart. Engineered to maintain consistent tension, they play a crucial role in the safety and integrity of structural connections.

The installation process involves a calibrated torque application, ensuring the right level of tension throughout the bolt’s lifespan, which is key to preventing structural failures under varying loads.

Application And Use Cases

These bolts are widely used in diverse construction projects, from high-rise buildings to bridges. Their reliability and ease of installation make them ideal for scenarios where structural integrity is paramount.

Case studies globally demonstrate the efficiency and durability of structures utilizing them, highlighting their importance in structural engineering.

Challenges And Considerations

Implementing tension control bolts in construction projects comes with a set of inherent challenges that demand meticulous attention and expertise. These bolts, essential for ensuring structural integrity, require precise installation techniques to function optimally.

This precision is crucial not only for the stability of the construction but also for the safety of the workers and future users of the structure. Therefore, it is imperative for industry professionals to be well-versed in the latest installation methods and safety protocols.

Read also A Business Coach’s Function in Inclusive Leadership

Adherence to stringent safety standards is another critical aspect. This involves regular training and updating of skills for the workforce, as well as ensuring that all equipment and materials used meet the highest quality standards.

Furthermore, it is essential to stay informed about the latest developments in bolt technology and installation methodologies. This includes understanding the nuances of different materials and how environmental factors can affect performance.

In addition, there’s a need for comprehensive documentation and rigorous inspection processes. Regular audits and checks during and after the installation process help in identifying potential issues early on, thereby mitigating risks.

Collaborative efforts between engineers, technicians, and safety experts are crucial in developing robust guidelines and solutions tailored to specific project requirements.

Effective communication and coordination among all stakeholders, including project managers, engineers, and construction workers, are vital for the successful implementation of bolts.

Training sessions and workshops can be instrumental in fostering a culture of safety and precision in construction practices.

Overall, the implementation, while challenging, is a critical component of modern construction.

By embracing continuous learning, adhering to safety standards, and fostering collaboration, the construction industry can overcome these challenges and ensure the longevity and safety of its structures.

Advancements In Bolt Technology

Recent advancements in bolt technology have further enhanced the capabilities of tension control bolts. Innovations in materials and design are leading to bolts with higher strength, better corrosion resistance, and increased durability.

These advancements are making these bolts even more suitable for challenging environmental conditions and demanding structural applications.

Environmental Considerations In Fastener Selection

In today’s construction industry, environmental sustainability plays a critical role in material selection. With their long lifespan and reliability, they contribute to sustainable construction practices.

By ensuring longevity and reducing the need for frequent replacements, these bolts help in minimizing the environmental footprint of construction projects.

Future Perspectives

Their future in structural engineering looks bright. With the industry leaning towards safer, more efficient, and sustainable construction methods, these bolts are becoming increasingly significant.

Their potential in supporting innovative, resilient building designs is immense, and ongoing advancements in technology promise to make them even more integral to future construction projects.

Tension control bolts have revolutionized structural engineering, improving construction project efficiency and safety, and opening new avenues for innovation.

As the industry evolves, these bolts will play a crucial role in enhancing the safety, sustainability, and efficiency of structures, standing as a testament to the industry’s pursuit of excellence.

Looking ahead, their influence on the future of construction and design is poised to be substantial, heralding a new era in structural engineering.